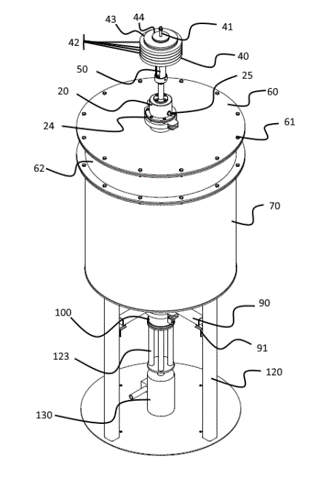

The design is related to the RSM test furnace used to measure the cohesive zone behavior of iron-containing raw materials used in blast furnaces. Dripping temperature measurement is made with a K-type thermocouple placed under the graphite collection chamber instead of a camera. In this way, drip temperature detection can be made at a lower cost. Another problem that the invention aims to solve is to prevent the cost disadvantage that arises as a result of the corrosion problem in the tubes in which the sample is placed. Within the scope of the study, it is anticipated that there will be an annual income of approximately 5,000 USD. Work within the scope of engineering, technical drawing and manufacturing was completed in 2018.

| Objective | To provide more practical and less costly measurement of the dripping temperature of iron ore melting and dripping test equipment. |

| Solution | Ore dripping temperature measurement is achieved with the help of a thermocouple instead of a camera. |

| Tailored Approach | Measuring the dropping temperature with a thermocouple instead of a camera and using a multi-piece graphite tube instead of a single-piece alumina tube used in measurement. |

| Reference | R&D RSM DEVICE, 01.12.2018 / 31.07.2020 (15 Months) 3 Designers and 19 Person Application Team, Start Up– 2020. |